OSU receives patent for new fermentation process

Tuesday, February 22, 2022

Media Contact: Alisa Boswell-Gore | Agricultural Communications Services | 405-744-7115 | alisa.gore@okstate.edu

Oklahoma State University was recently issued a patent that could significantly increase biofuel and chemical yields while reducing carbon dioxide emissions.

Hasan Atiyeh, professor of biosystems and agricultural engineering, created a new co-fermentation method that turns sugars into alcohols, organic acids and ketones without the environmental impact.

This co-fermentation process adds naturally occurring microorganisms (bacteria) into the fermentation process of plant substances, such as corn, grass and wood. The process combines sugar-fermenting and gas-fermenting bacteria while capturing carbon dioxide, which is also fermented to create more biofuels.

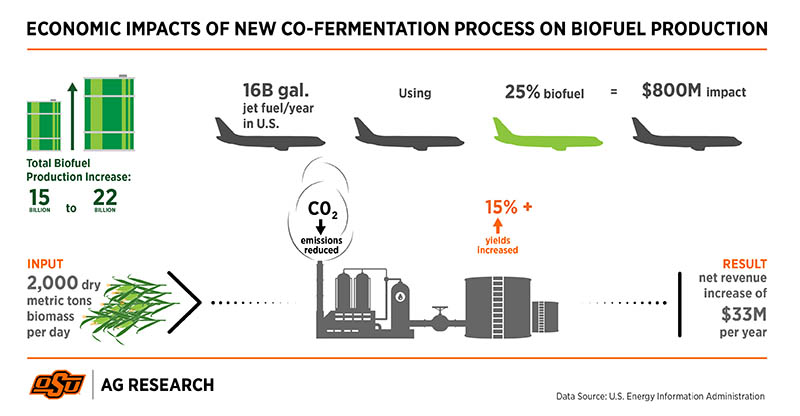

“This is important because the U.S. produces over 15 billion gallons of biofuel per year and is expected to increase that to 22 billion gallons per year,” Atiyeh said. “This co-fermentation process presents potential environmental benefits when compared with conventional and emerging biofuel production pathways while increasing yield and profitability for biorefineries.”

The technology could potentially increase product yields by more than 15 percent while lowering carbon dioxide emissions compared with conventional processes. Atiyeh said his research estimated that using 2,000 dry metric tons of biomass per day with this novel co-fermentation process could increase a biorefinery’s net revenue by $33 million a year compared with traditional fermentation methods.

“For example, more than 50 percent of the carbon in sugars is lost to production of hydrogen and carbon dioxide, which are wasted during butanol production via the traditional fermentation method,” Atiyeh said.

The method’s economic impact could also extend to the jet fuel and fossil fuel industries. Butanol has been produced by traditional acetone-butanol-ethanol (ABE) fermentation using molasses, starches and lignocellulosic biomass, but the ABE process suffers from low conversion yields and higher environmental impact. About 16 billion gallons of jet fuel are used in the U.S. each year, and if biobased butanol replaced 25 percent of that amount, it would have an economic impact of more than $800 million.

“We can use this technology to convert the carbon dioxide emissions from corn biofuel facilities into more biofuels,” Atiyeh said. “Increased conversion efficiency of renewable raw materials to biofuels makes the process viable.”

Atiyeh said the technology will initially be marketed to the corn and cellulosic ethanol industries. More than 15 billion gallons of corn ethanol are produced in the U.S. each year, and about 45 million tons of carbon dioxide per year are emitted from over 200 U.S. biorefineries.

“Commercialization of technology is key to the development of biobased product and energy advancements,” said Mari Chinn, department head for the OSU Department of Biosystems and Agricultural Engineering. “Exploration and development of technologies to convert gas waste into renewable fuels and useful products supports innovation in carbon capture and sustainability.”

Atiyeh has more than 18 years combined industrial and academic experience in research and development in biological conversion technologies, alternative energy sources, cell metabolism, reactor design and sugar fermentations for production of biofuels and biobased chemicals.

He currently holds three additional U.S. patents on technologies related to gas fermentation for making biofuels and biobased products. OSU has received 80 technology patents since 2011.

OSU Ag Research is Oklahoma's premier research and technology development agency in agriculture, natural resources and the life sciences.

This project was supported by Agriculture and Food Research Initiative Competitive Grant no. 2019-38502-30120 from the USDA-National Institute of Food and Agriculture for $117,089.